C9 incorporates new useful data on cost of workshop techs into key reports to provide better data on profitability and performance of workshop departments.

To use this data some setup and management is required also change in processes. Alot of setup involves enabling payroll functionality in c9. It doesn't require running full payroll through c9 to access the core useful functionality though the more the payroll data is used the more useful data c9 will provide.

Workshop techs must use clocking to enable new cost reporting features. C9 will not compute costs off hours entered on job since hours here are editable and designed to represented billed hours, not actual hours, it is computed strictly based on clocking activity.

First. Defining Efficiency / Productivity and Proficiency

Efficiency : Is the ratio of billable hours to clocked hours. The more time techs work on billable work vs unbillable work the more efficient they are. It is possible for a tech to have >100% efficiency if what is recorded on a job card for hours is more than what they actually timesheeted.

Productivity: Is the # of hours a tech clocked as a ratio of their agreed employment hours. So a tech can have >100% productivity if they work more hours than what their employment terms are

Proficiency : is Efficiency multiplied by Productivity. Is is effectively the ratio of the billable hours vs their contracted / agreed employment hours.

Setup requirement. From order of most important to least important and functions setup enables.

| Setup |

Functionality Gained |

| Techs to use clocking to clock onto jobs |

Compute efficiency for proficiency report |

- enable payroll access

- Configure staff hourly rate or yearly salary

|

Track cost of labour on jobs. displayed in key reports |

- enable payroll employment types

- map types to staff

|

- Fine tune accuracy of cost estimates to factor in actual work hours and overtime

- Compute productivity for proficiency report

|

| Maintain leave and holidays data |

Fine tune accuracy of productivity figures in proficiency report |

| Full payroll : implement pay runs |

Provide non COGS labour estimates in profit summary report |

| Map staff to correct departments |

Breakdown payroll figures in profit summary report based on department |

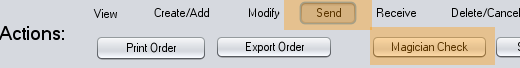

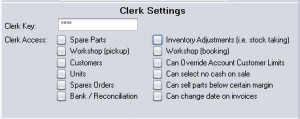

Tech Clocking

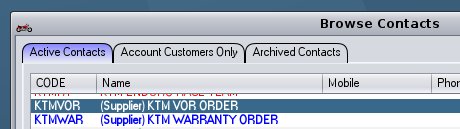

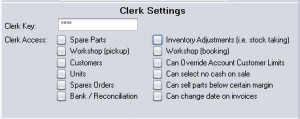

To make use of data techs need to clock onto jobs in c9. Techs need to be assigned a unit clerk key.

Workshop -> Utilities - >Staff

Select staff member who is a tech and click change. Key in a unique secret clerk key for the tech. also tweak clerk settings for oher things in c9 techs can access. Select none of the options for techs that have no other responsibilities in c9 other than logging time.

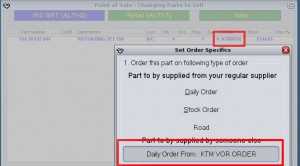

Now tech can access clocking via 'Clocking' option in top of c9 or via view workshop jobs. They key in their clerk key and then key in job number they want to clock onto. Techs must clockoff end of day and also clock off when going on break idle etc.

You can configure non job related items a tech can clock onto. workshop -> Utilities -> Clocking reasons.

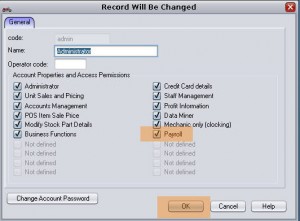

Enable Payroll Access

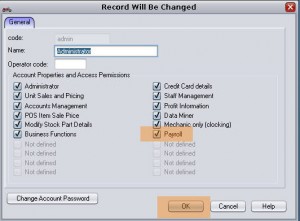

Setup -> other settings -> Login Users.

Select a privileged user and click on Change

Select payroll option and click OK.

Logout of c9 and re-login as the privileged user

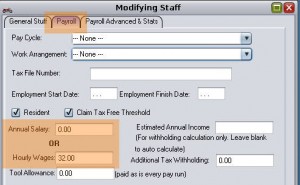

Configure Staff payroll particulars

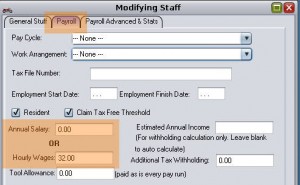

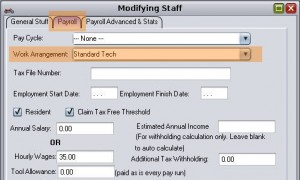

Now in Workshop -> Utilities -> Staff you can access payroll tabs. Key in either hourly wage or salary into appropriate slot.

Note: C9 cost computation adds a compulsory superannuation figure. Make sure wages or salary figure is before compulsory super

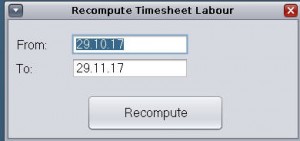

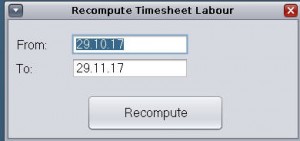

Tip : setting pay data only applies to clocking performed after the change. To help get things started to extract useful data after initial setup you and run a utility in c9 that will recompute cost of labour on already clocked time based on current payroll configuration. It is only useful for dealers that use clocking already though.

To access : workshop -> utilities -> recompute TS. Key in period (defaults to a month prior until today) and run recompute

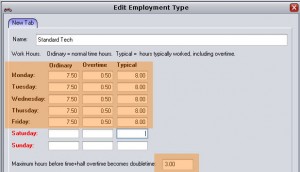

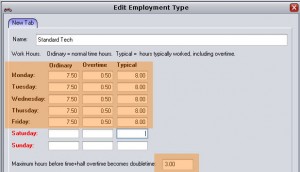

Configure Employment types

Employment types allows you to configure typical weekly hours worked and overtime hours. you may need to configure more than one for techs that work different conditions. e.g. if your techs typically work monday to friday that would represent a base employment type, but if you have one tech that only works 3 day weeks, they will require their own employment type to manage the hours they specifically work.

To manage employment types . Business - >Payroll -> Setup -> Employment types.

Key elements as relevant for workshop cost computation highlighted below

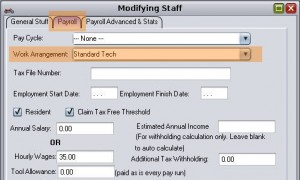

Map Employment types to staff

Employment types are mapped to staff back in Workshop -> Utilities - >Staff. On payroll tab

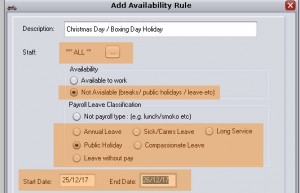

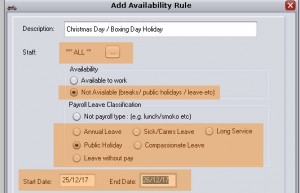

Maintain Holidays and Leave

Public holidays and leave is managed via Business -> Payroll -> Manage Leave/Holidays

Full Payroll

too much to cover here to explain full payroll. In essence if there are payruns tracked in c9 c9 will use this data for profit summary report.

firstly need to define pay cycles. Weekly etc. Business -> Payroll -> Setup -> Pay Periods

Next, business -> Payroll -> payruns to create payruns. No requirement to finalise payruns to get data into profit report. Pay runs can be created and left in Active status and will influence profit summary report.

Map Staff to departments

Workshop -> Utilities -> Staff. On main screen is option to select department staff memory principally works in . This influences grouping in profit summary report

Orange zone : select on of these to flag staff member as a workshop tech

Green zone : non workshop roles that group within the profit summary report